Challenges

One of the largest chemical distributors in the country were mired with high average inventory age of the chemicals that they imported from across the globe. This led to:

- High inventory cost

- Low capital turnover

- Wastage because shelf life of chemicals

These challenges got accentuated because of the seasonality nature of the business.

At times, they also faced the challenge of the other extreme where they had a demand but were not able to fulfil the demand because of uner-stock. This led to potential revenue loss.

Solution

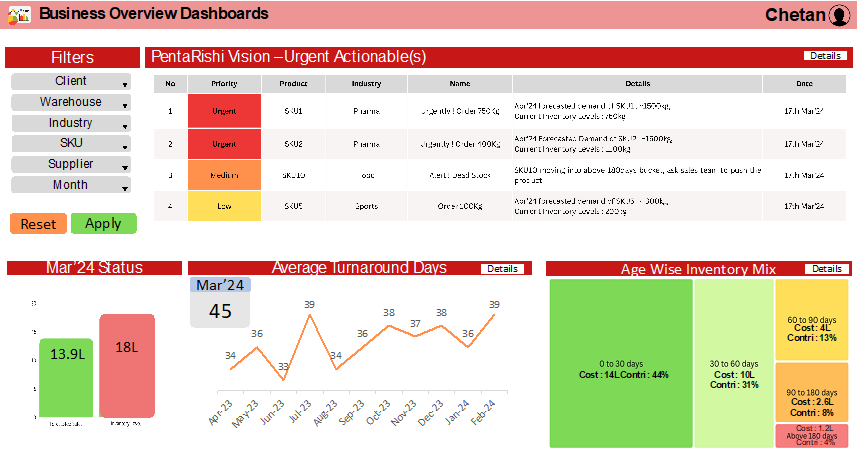

They contracted Pentation for deploying AI Powered Demand Forecast Tool. With this tool, they are able to know:

- Their expected demand for each SKU:

- for the next 1 – 12 months

- warehouse-wise

- suppliers who can provide these SKUs and the average delivery timelines

- The capital impact of the expected demand

- Qty of SKUs which are likely to get into 90 – 180 days and >180 inventory age buckets at the end of the month along with:

- Capital impact

- Top 5 potential buyers

In addition, they also got to see many management KPIs such as:

- Profitability of each SKU by taking into account all the costs.

- Average inventory age for the last few months

- % of inventory in different inventory age buckets

- Top suppliers and their % share of wallets over the last few months

- Top buyers and their % contribution to their overall revenue over the last few months

- MoM and YoY comparisons

Business Impact

Deployment of Newton has improved the alignment between demand and supply. This led to:

- improved capital utilisation,

- reduced inventory cost,

- reduced potential business loss and